-

Global

Global-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- BUSINESSES

- |

- Contact

- |

-

Global

Global-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- BUSINESSES

- |

- Contact

- |

You are browsing the product catalog for

You are viewing the overview and resources for

- News

- Industrial AI: Unlocking the Superpowers Within Your Operation

Industrial AI: Unlocking the Superpowers Within Your Operation

AI-enabled technologies can help continuously monitor equipment, empower employees with real-time data and enhance quality management.

What if you could see the future, upskill your team and tap into real-time intelligence and with a single command? These are a few ways in which industrial operations can progress on their automation journeys with the help of artificial intelligence (AI).

Industrial leaders are navigating how AI can benefit their operations, and some are already reporting progress. Nearly two-thirds of industrial leaders surveyed by Honeywell cited efficiency and productivity gains among the most promising benefits of implementing AI in their operations, and nearly 60% reported better decision making due to real-time data generation.

Technology can play a role in taking your industrial automation journey to the next level and unleashing the superpowers of your operation and team. Here’s how:

Predictive Analytics

Superpower: Predicting the Future

AI- and ML-powered technologies can give industrial workers forward-looking insights to help them make more proactive decisions about their operations.

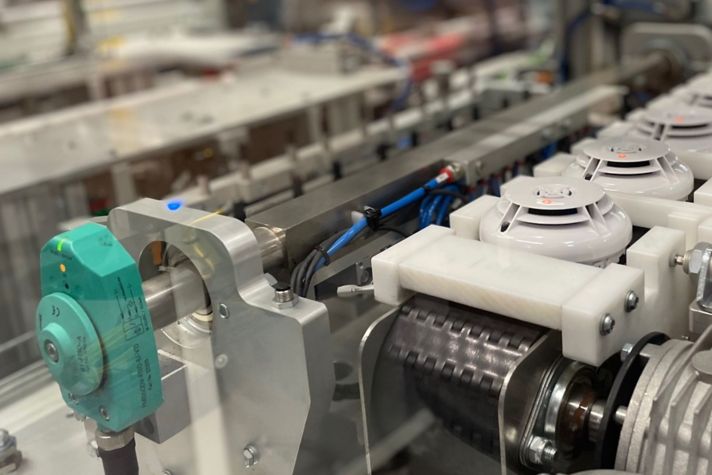

In an industrial setting, workers are monitoring sometimes thousands of pieces of equipment. Instead of relying on human senses to detect a potential maintenance issue – such as inspecting equipment and listening for an unfamiliar noise – operations can make use of software to predict when a piece of equipment is likely to need repairs, which can help prevent costly downtime. This is known as predictive maintenance, and it can help operations continuously monitor the equipment, not just at the time of human inspection, as well as improve safety by preventing people from entering physically hazardous areas.

Take digital twin technology, which can give operations a glimpse into future scenarios. A digital twin is a virtual copy of a physical asset that allows operators to simulate the actual process against expected parameters. This can help operations with training and upskilling teams. For example, new workers can practice starting up and shutting down plant operations via the digital twin to get acclimated with day-to-day processes.

Workforce Excellence

Superpower: Real-Time Intelligence

Organizations are facing challenges such as talent shortages, technology shifts, skills gaps and regulatory compliance. In industries where human error accounts for 30% of accidents, AI-powered technologies like virtual reality and augmented reality can be used to facilitate training and onboarding of new employees and upskill existing workers. These solutions can help reduce onboarding time and increase safety through remote and virtual training simulations.

One example is Honeywell’s Field Process Knowledge System (PKS), which uses generative AI technology to provide field technicians and operators assistance at their fingertips – such as easier access to required documents, procedures and information they need on their device to complete their work. The Field PKS also helps workers achieve more by automating reporting, allowing teams to focus on other projects.

Quality Management

Superpower: Being Proactive, Not Reactive

In general, AI-powered technologies can help industrial operations monitor and improve quality by analyzing data from multiple sources, such as sensors and historical records, to detect anomalies, identify root causes and recommend corrective actions.

Consider companies in the life sciences sector, where quality management is key to the safe and efficient delivery of new drugs. Automation can help operations prioritize safety and avoid manual errors. For example, TrackWise Digital, Honeywell’s AI-enabled quality management solution, allows customers to utilize natural language processing and machine learning to help enhance signal detection, operational efficiency and employee productivity to help leaders avoid downtime and improve decision-making.

Learn more about how AI is enabling autonomous industrial operations, and check out the Industrial AI Insights report for a deeper dive on the latest trends.

Copyright © 2025 Honeywell International Inc.