-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- BUSINESSES

- |

- Contact

- |

-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- BUSINESSES

- |

- Contact

- |

You are browsing the product catalog for

You are viewing the overview and resources for

- News

- Mission to Mars: How Innovation Will Take Us There

Mission to Mars: How Innovation Will Take Us There

Phoebe Henson, whose work focuses on human life support systems for space, breaks down the unique challenges of a mission to Mars and how innovative technologies will make it possible.

It's an exciting era for space exploration, and one of the next milestones on the horizon is getting humans to Mars.

A journey to Mars is different than a mission to the Moon in many ways. For one thing, it's a much longer trip.

The average distance from Earth to the Moon (accounting for rotation in orbit) is around 238,900 miles, whereas the distance from Earth to Mars -- the Red Planet -- is an average distance of 140 million miles.

What does that translate to in terms of travel time?

A NASA mission to Mars is slated to take roughly a year each in traveling to and from the planet, with an additional year dedicated to proving that we can live there.

In 2018, NASA pointed to the trend of technological advancement since the original Apollo mission as a sign that favors a successful manned Mars mission in the not-too-distant future: “Mars may be 200 times farther than the Moon at closest approach, but we may be thousands of times more prepared to achieve this.”

In other words, with the rate of technological breakthroughs in development now, a mission to Mars may be closer than you imagine.

Keep reading to learn more about groundbreaking research that could provide something critical to getting astronauts to Mars and helping them stay there: a life support system that allows them to breathe even amid extremely oxygen poor atmospheric conditions.

Innovations to astronaut life-support systems are key

To understand the technology that will allow humans to breathe on Mars in the future, it's important to learn about the life support systems that allow people to breathe on the International Space Station (ISS) today.

The ISS uses a Space Environmental Controls and Life Support Systems (ECLSS) system that converts carbon dioxide (CO2) to oxygen. The current system, the Carbon Dioxide Removal Assembly (CDRA), has limitations compared with the needs a mission to Mars presents.

The current process of harvesting oxygen from CO2, or the Sabatier reaction, can be used for the relatively close ISS and recover 50% of oxygen. However, if the same life support system were to be used for the Mars mission, that percentage translates to a significant amount of oxygen that then needs to be transported to Mars.

“For Mars, adding the mass of the additional required oxygen even at 50% recovery of CO2 is just way too high. Adding a technology like Methane Pyrolysis enables the recovery of 100% of oxygen from CO2 and decreases the mass required for a mission to Mars,” said Phoebe Henson, Senior Life Support Systems Engineer, Human Space Research and Development.

“We don’t want the mission to be cost prohibitive,” she says, referring to the cost per kilogram of anything launched into space. While the cost per kilogram has decreased for low-orbit flights, every kilogram you can leave behind on exceptionally long trips counts even more.

Henson’s work at Honeywell focuses on space life support systems, specifically a CO2-removal system known as the carbon dioxide removal by ionic liquid system (CDRILS) technology.

It uses “a regenerable ionic liquid to capture the CO2 from the atmosphere of a spacecraft,” Henson said. CDRILS combined with a Sabatier reactor and the Methane Pyrolysis technology create a completely closed-loop life support system that is able to recover 100% of oxygen from CO2. Recruited out of Arizona State University while completing an engineering internship with Honeywell, Henson has 12 patents relating to the carbon harvesting system.

Henson explained that the durability of the main components of CDRILS means it can be provided in a much smaller package - which is good for future astronauts on the mission to Mars.

In addition to major reductions in volume and mass, CDRILS also requires less power than the CO2 removal system used at the International Space Station.

The system is also a major upgrade in another key area: it has less equipment mass and requires less maintenance.

“Astronaut time is valuable. For a mission to Mars, we can't have astronauts spend all their time working to maintain a technology,” she said. “We need our astronauts there to go and do valuable science, set up equipment for future missions, and so on.”

The greater reliability of the system is also meant to ensure ongoing safety over a much longer timeline.

Preliminary missions will help prepare for the future

Henson explained that one of the challenges with a mission to Mars is the latency in communication between Earth and Mars, as opposed to the near direct communication between the ISS and Mission Control in Houston. According to NASA, the delay in communication between Mission Control and Mars will range from 4 to 24 minutes.

“The sensors need to be extremely reliable. When we go to Mars, if there's an issue, we can't be waiting on Mission Control back home to execute on solving that problem,” Henson said.

“So it's not just about the sensors, but it's also about the control system and just having astronauts that are trained in every possible scenario that could go wrong. Everything is going to need to be a lot more self-sufficient,” Henson states.

Speaking of ongoing testing, the upcoming NASA Artemis II (manned orbit around the Moon) and Artemis III (manned mission on the Moon) missions will test capabilities for deep space exploration. Honeywell’s continuing partnership with NASA in space exploration include involvement in various aspects of the Artemis I launch, which sent the unmanned Orion spacecraft around the moon to prove capabilities for future missions.

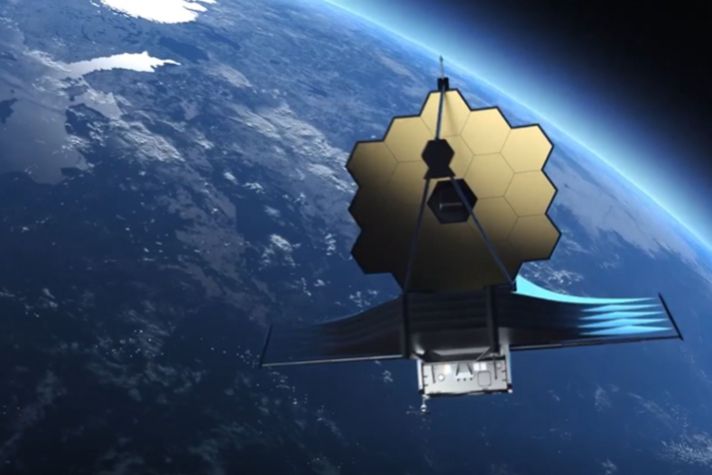

Pictured: NASA's Artemis I, an uncrewed mission to the mission, on launch day in November 2022. The Artemis program plans to bring humans back to the moon, as well as to Mars. Honeywell provided the full navigation and guidance system for the Artemis I launch vehicle, and throughout the course of the Artemis program, Honeywell technology will play an increasingly critical role in the Orion spacecraft and the Artemis missions.

“NASA is using the moon as a kind of steppingstone to Mars,” Henson said.

“We will have some communication latency, not a very big one, but I think that being further away will help us build the capability to be more self-sufficient with a lot less risk than a mission to Mars. It'll also give us the opportunity to test capabilities like potentially using Martian or lunar resources in order to create valuable things for the mission, like fuel,” Henson said.

“We know the first companies to be able to create fuel on the Moon or Mars will create a lot of value for NASA and commercial companies going to space.”

As far as inspiring the next generation of innovators, Henson said, “I hope that when kids hear we're going back to the moon in preparation for the Mars mission, they're just as amazed as I was when I learned about the ISS for the first time.”

Want to learn more about what makes the Mars mission unique? Check out this episode of The Future Is… podcast featuring Amanda Childers, Lead R&D Scientist, whose work focuses on recovering oxygen following the removal of CO2 from the air.

Copyright © 2025 Honeywell International Inc.