-

Global

Global-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- BUSINESSES

- |

- Contact

- |

-

Global

Global-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- BUSINESSES

- |

- Contact

- |

You are browsing the product catalog for

- News

- Top Innovations of 2020

Top Innovations of 2020

The pandemic caused global challenges and spurred new inventions

This year was like no other. It was defined by the rapid spread of COVID-19 around the world.

In response, it changed the way people worked and lived, leading to innovations that increase safety for travelers and help protect people in buildings.

We also created new technologies to help industries in the short term combat the pandemic and prepare for the future.

Here are the top innovations of the year:

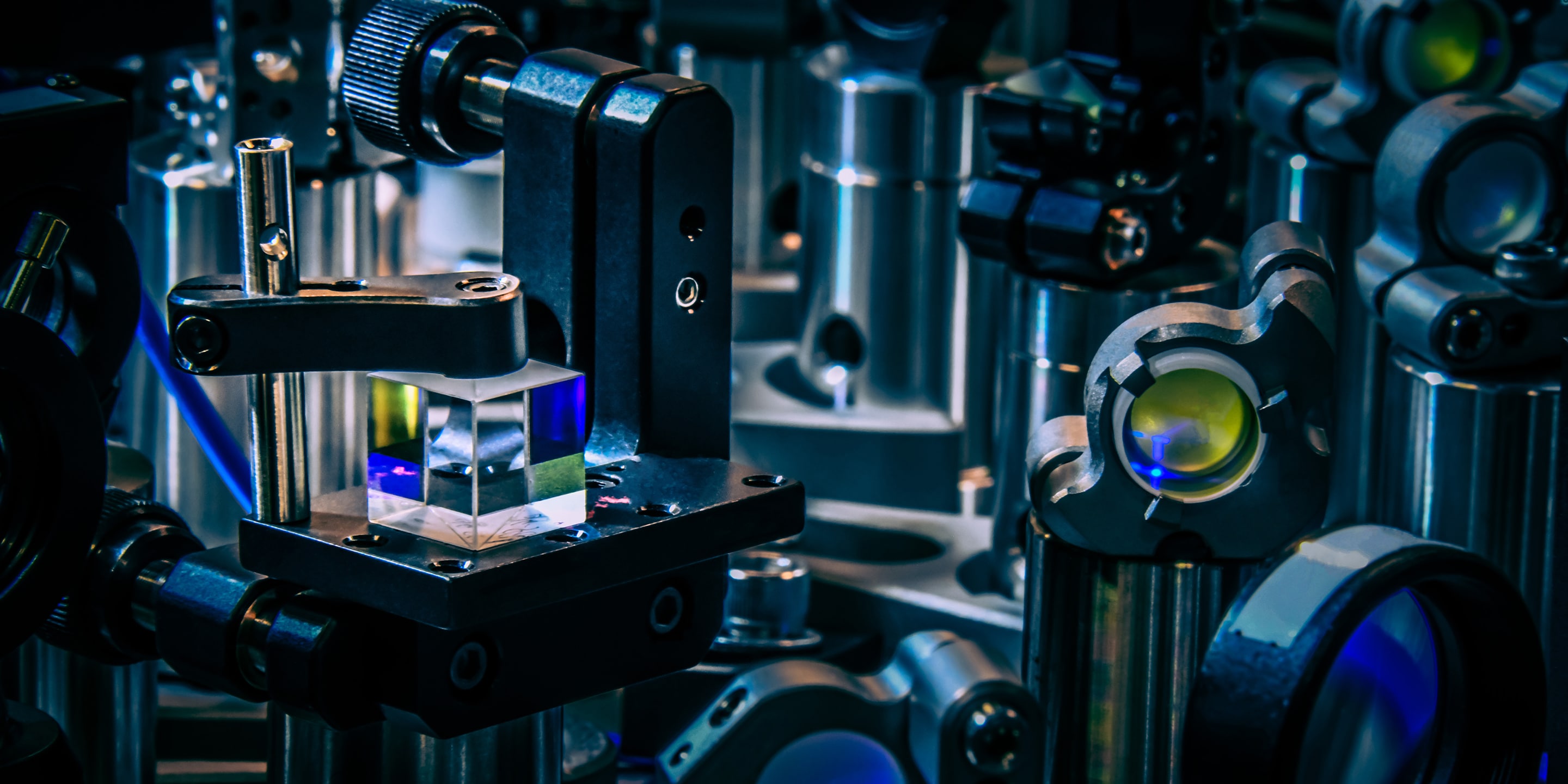

Quantum computing becomes reality

What: This year, we released Honeywell System Model H1 quantum computer with a Quantum Volume of 128. The computer is now available commercially to enterprises seeking to leverage quantum computing as part of their technology roadmap.

Why it’s innovative: A focus on reducing errors and producing the highest quality quantum operations builds trust that quantum computers can deliver accurate and reliable results to problems that can currently be confirmed using classical methods. As these problems grow beyond what classical computers can handle, trust in the accuracy of the underlying technology becomes paramount.

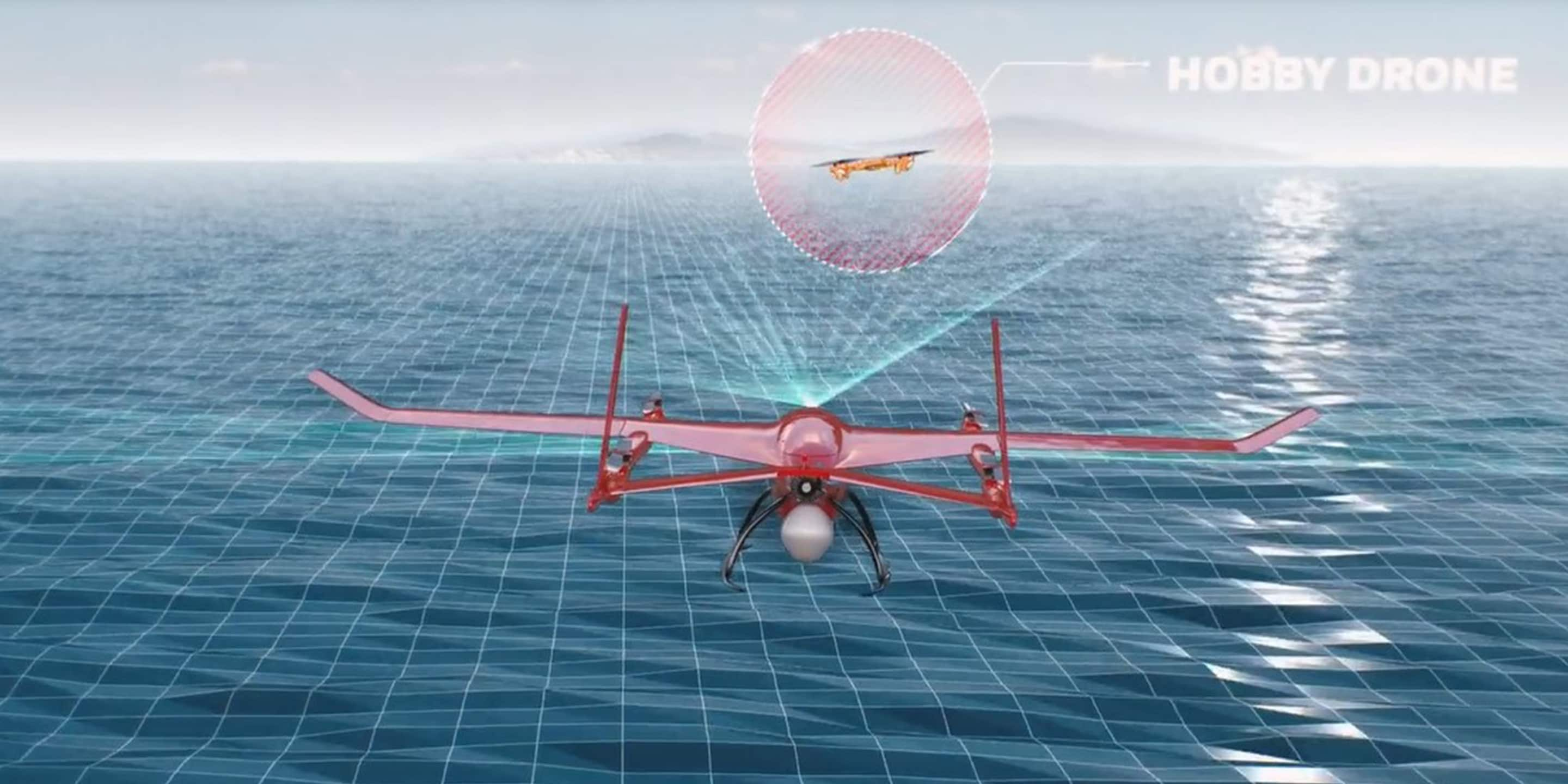

Collision-avoidance for drones

What it is: A lightweight radar, the IntuVue RDR-84K Radar System, can help detect other air traffic, birds and weather.

Why it’s innovative: In addition to detecting obstacles, it can provide alternative navigation if the primary guidance fails and assist with accurate, automated landings. It saves weight and space by replacing other sensors, which is key for Urban Air Mobility (UAM) vehicles like air taxis and Unmanned Aerial Vehicles like drones.

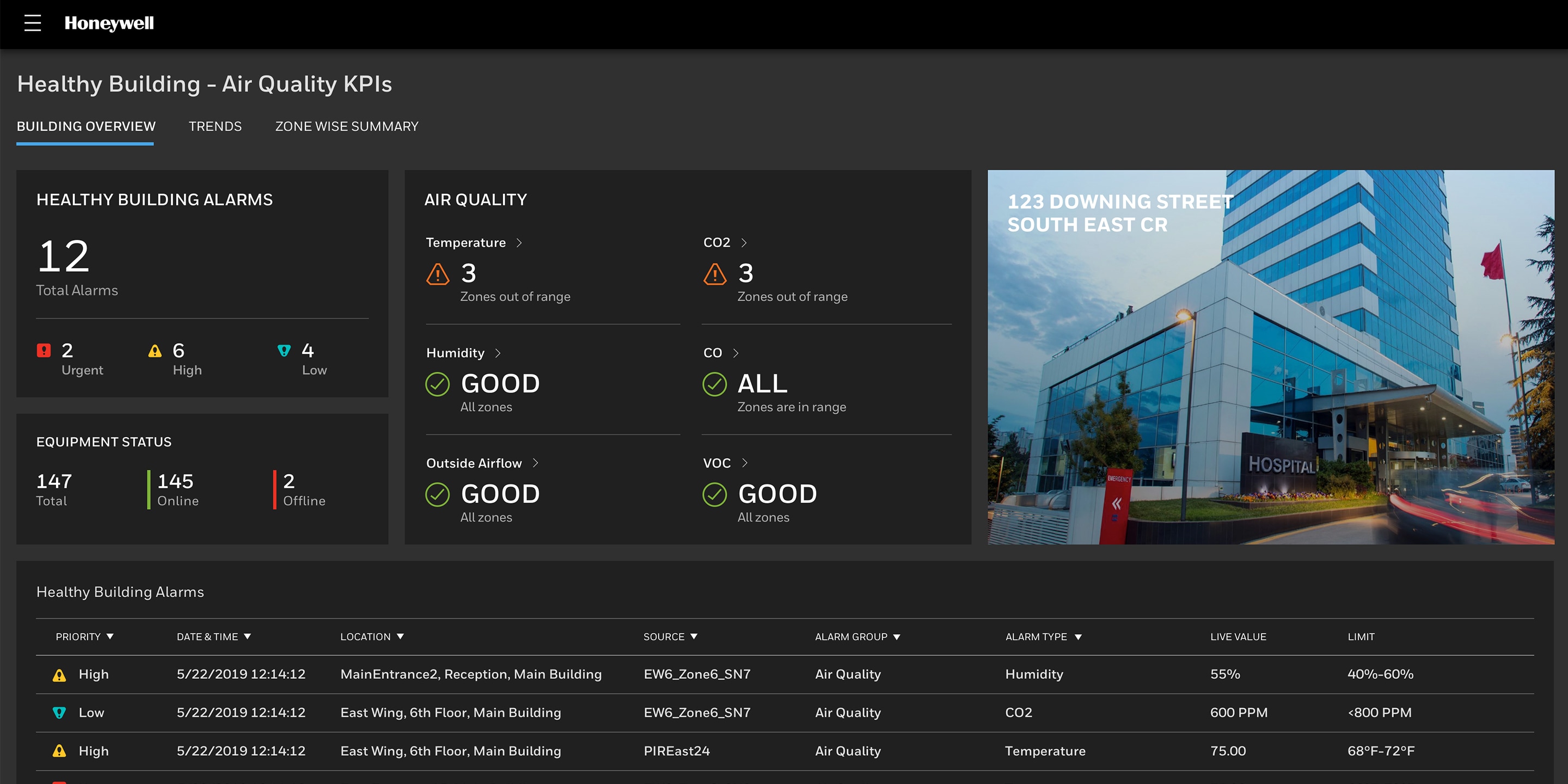

Buildings that protect people

What it is: As the pandemic spread around the world, offices became vacant. But certain buildings had to be kept up and running, including manufacturing facilities and hospitals. We used technology that analyzes air quality, safety and security to building owners minimize potential risks of contamination. That includes monitoring both the building environment and building occupants’ behaviors.

Why it’s innovative: Technology helps reassure occupants that buildings are safer to return. Our Healthy Buildings solutions can support the needs of any building and features specific solutions for premium commercial buildings, airports, hospitality, healthcare, stadiums, schools and universities.

UV-C light used in new ways

What it is: Honeywell’s UV Treatment System uses UV-C light inside aircraft cabins treating high-touch surfaces such as trays, seats, aisles and luggage bins.

Why it’s innovative: UV-C light as a disinfectant itself isn’t a new concept. It’s been used for about four decades to disinfect drinking water, wastewater, and more, according to the International Ultraviolet Association (IUVA). But applying the treatment to a plane cabin is a big deal. The system can run the length of a narrow-body aircraft in 10 minutes or less.

Visibility to what’s in the air

What it is: Particles in the air are no longer invisible. With the Air Detective, we use technology analyze an air sample and record them with holographic images. Those images are then sent to the cloud for on-the-spot analysis of the types of spores, pollens and other airborne particles.

Why it’s innovative: A powerful holographic microscope powered by AI allows heating, ventilation and air conditioning (HVAC) technicians to take a snapshot of the air inside your home. No need to wait for a sample to get sent to a lab.

Operating remotely

What it is: From fire alarm systems to industrial facilities, we helped the world pivot to remote operations. For example, Honeywell’s Connected Life Safety Systems enable fire technicians to operate a building’s fire panel with the cloud. Meanwhile, our Honeywell Process Solutions pivoted a critical process control facility in Orange, Texas to remote operations.

Why it’s innovative: Many facility maintenance teams are working with reduced staff and have limited access to facilities due to shutdowns. With remote operations, fewer staff can be on-site and critical tasks can still be performed.

Machine learning cyber-protection

What it is: As soon as a hacker attempts malicious behavior in an industrial setting, our machine-learning based application knows about it.

Why it’s innovative: Identifying security issues in industrial control systems and Industrial Internet of Things technology is increasingly important. Communications abnormalities can indicate hardware problems, anomalies, security and configuration issues and even cyberattacks.

3D-printed engine parts

What it is: We created the first certified, flight-critical engine part using 3D printing, formally known as additive manufacturing.

What it is: We created the first certified, flight-critical engine part using 3D printing, formally known as additive manufacturing.

Why it’s innovative: By 3D printing critical parts, manufacturers can produce parts more quickly and in smaller quantities. During this process, components are built from the bottom up, with layers of powdered metal fused on top of one another using a laser.

Copyright © 2024 Honeywell International Inc.